Magnetic pulse welding: Identifying binding mechanisms

Introduction

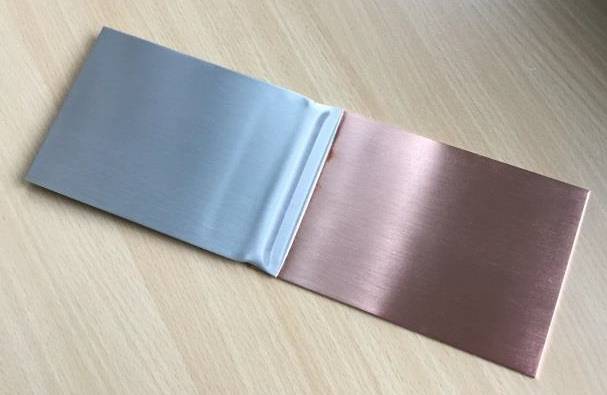

Magnetic pulse welding (MPW) is a welding process to join two workpieces. A magnetic pulse is used to accelerate one workpiece (the flyer) such that it impacts the other workpiece (the target) at a high velocity under a certain angle. The process is used for example in the automotive industry to join dissimilar metals.

The task

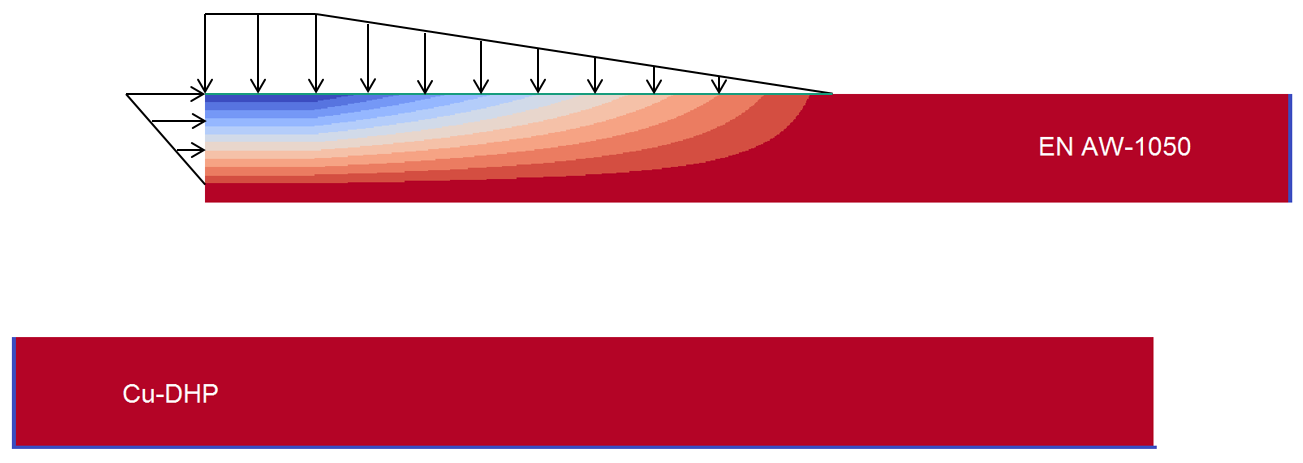

An open question is which process and material properties influence the quality and strength of the obtained joints. This topic as addressed in a collaboration between the Fraunhofer IWM, the Fraunhofer IWU and the TU Chemnitz within a Fraunhofer Research Program. To clarify the question it is necessary to identify the local conditions during the welding process such as temperature, pressure and shear stress. Smoothed particle hydrodynamics simulations are therefore used to model MPW with an aluminum flyer and a copper target. As a first step, the force experienced by the flyer due to the magnetic pulse must be modelled adequately as it determines the flyer motion.

Results

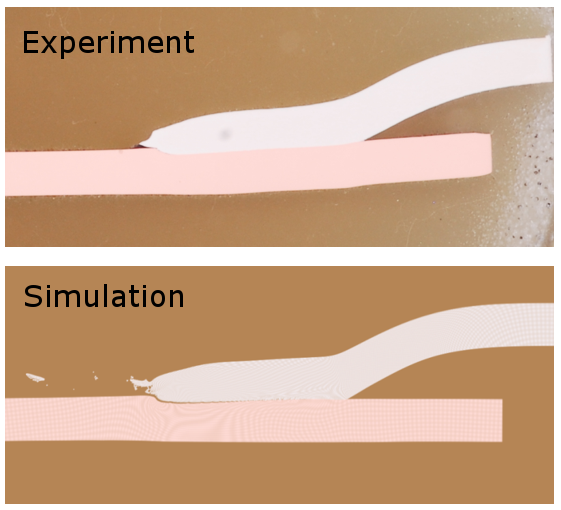

The overall quality of the simulation model is assessed by a comparison of the final deformed shape of flyer and target after the MPW process. The results shown in the figure on the left confirm that many details of the complex deformation pattern are reproduced by the simulation.

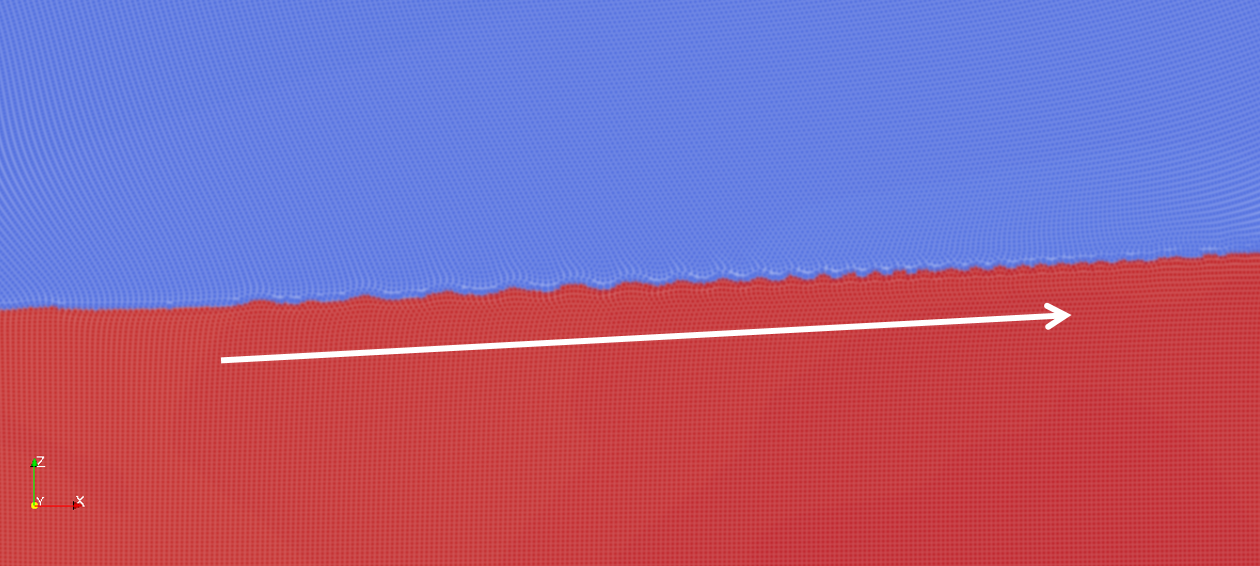

Along the joint interface a wavy pattern is often found in experiments. This observation is reproduced in the numerical simulations. Along the contact line the interface between the workpieces in initially flat. Then, it develops waves with decreasing wavelength along the contact line. Finally the interface becomes flat again. This effect is addressed to a Kelvin-Helmholtz instability. Furthermore, the simulations predict a somewhat elevated temperature field at the interface with peak values around 400 °C.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM