Cohesive powders: a particular challenge

Introduction

Dry pressing is an established process in the production of components from technical ceramics, sintered steels or hard metals. An inhomogeneity in the density, which may result from the die filling, is not neutralized during the subsequent process steps and might lead to substantial deviations in size and shape. In order to track such problematic variations of density, simulation tools were developed at the Fraunhofer IWM which are tailored for the process of die filling. Using these tools, customers gain indications for further optimization of their production process.

The task

Especially for cohesive powders with poor flowability and a tendency to clump, it is important to ensure that the die is filled homogeneously. The discrete element method (DEM) simulates the behavior of a multitude of individual grains and, therefore, models the powder quite realistically. The interaction between the grains determines the complex powder characteristics during the flow process. Grains are pressed together, thereby increasing their cohesion. If sufficient energy is applied, e.g. during the impact on the ground, the contacts are released again. These effects are not covered sufficiently by the usual DEM force laws. To overcome this shortcoming, specific force laws were developed which take into account the load history of the individual contacts. Thus, the material model reacts on external influences and dynamically adopts the powder characteristics corresponding to the process conditions.

Results

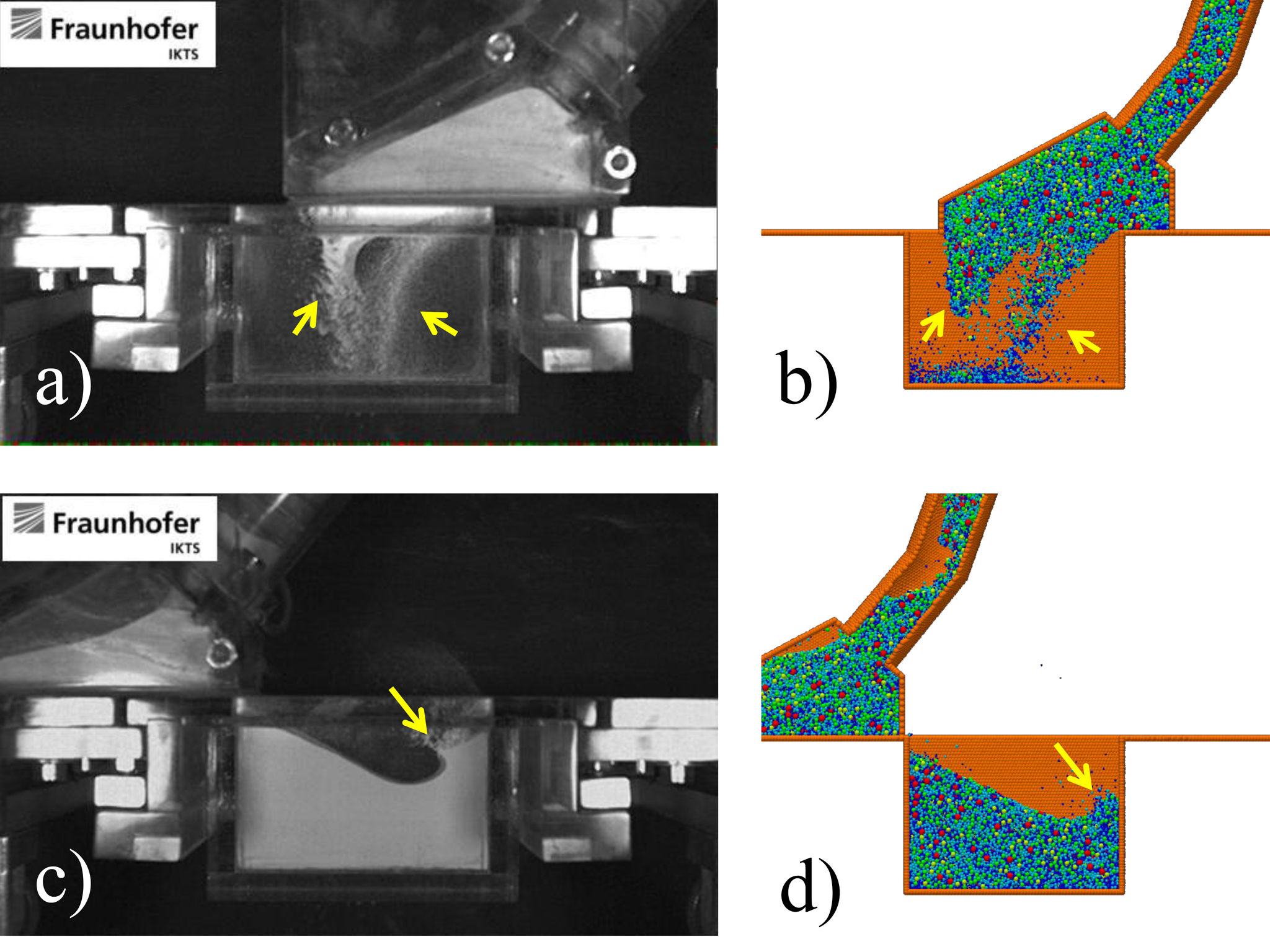

The method is capable of correctly capturing the complex behavior of real powders. Comparing the simulation results with experimental findings in figure 1 shows, that both the appearance of different flow regions (a, b) in the early stage of filling, as well as the dynamic fluidization later on (c, d) are realistically captured by the simulation model. The simulation is now available for a wide range of powder technology professionals. Our customers from the areas foodstuffs, pharmaceutics, ceramics or hard metals can use the simulation to specifically optimize their processes gaining higher process stability, lower scrap rates and higher product quality.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM