Dental care: High cleaning efficiency without damage

Introduction

For the formulation of the complex interactions occuring during dental care, account needs to be taken of the complex mechanisms and requirements of biological materials. The objective of the use of toothpaste is to achieve an efficient cleaning effect by the removal of organic material from the teeth. The disposal of oral biofilms can be achieved by surface active components in combination with abrasive particles added to the toothpaste. On the one hand, this increases the cleansing effect of the toothpaste, on the other hand, the use of abrasive particles increases the risk of wear and degradation of the enamel, which can not be regenerated.

A trustworthy identification and assessment of the different influencing factors, i.e. cleaning efficiency, polishing properties and minimal abrasion in the near surface area, poses a major, to date, not entirely solved challenge. Gaining insight into the mechanisms of the interactions will help to improve the development of dental health care products.

The task

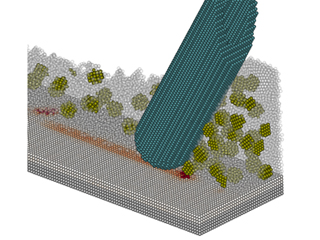

The aim of the investigations is to develop new methodological approaches for the metrological detection and evaluation of the occurring interactions between the toothbrush and the abrasive particle enriched toothpaste. In order to achieve new insights, the process of brushing the teeth will be reduced to a tribological system consisting of a single toothbrush filament, the enamel and the corresponding suspension consisting of the toothpaste, abrasive particles, and water. Besides the assessment of the abrasive character of the toothpaste, the friction and cleaning behavior of the toothbrush filament is also examined closely.

The principal goal is to develop a detailed understanding of the mechanical interactions occurring during health care processes. For this, the numerical code SimPARTIX® is used in order to assess the influence of different procesess and material parameters on the stress input and hence on the abrasion risk on the enamel surface. The toothbrush filament can be varied in various parameters, i.e. elasticity, normal force and brushing velocity, while the suspension parameters can be varied in material parameters, i.e. viscoelastic behavior or the shape, size and material of the abrasive particles.

Results

The numerical investigations demonstrate that various parameters have an impact on the cleaning efficiency of the combined system toothpaste and toothbrush. An increase of the viscosity of the suspension will yield on one side the stress input onto the enamel surface, on the other side it increases the capture probability of abrasive particles by the toothbrush filament increasing the cleaning efficiency. Both are relevant factors for the overall tribological system toothbrush-toothpaste-enamel.

The aquired insight into the dental care processes can now be used by industrial partners for enhanced product development. The numerical models and simulations can be applied for the optimization of toothpastes with regards to an enhanced cleansing efficiency along with a low wear risk on the enamel.

The applied methodology can be extended to other materials such as skin or dental composites that have similar issues concerning the friction and wear beahvior.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM